Power-to-X Technologies

The Power of Engineering

With more than 60 years of experience and extensive competence in power-to-X technologies, we are the ideal partner for you. Put your trust in our expertise in the field of water electrolysis, hydrogen derivatives and e-Fuels.

Get into contactGet into contact with our experts.

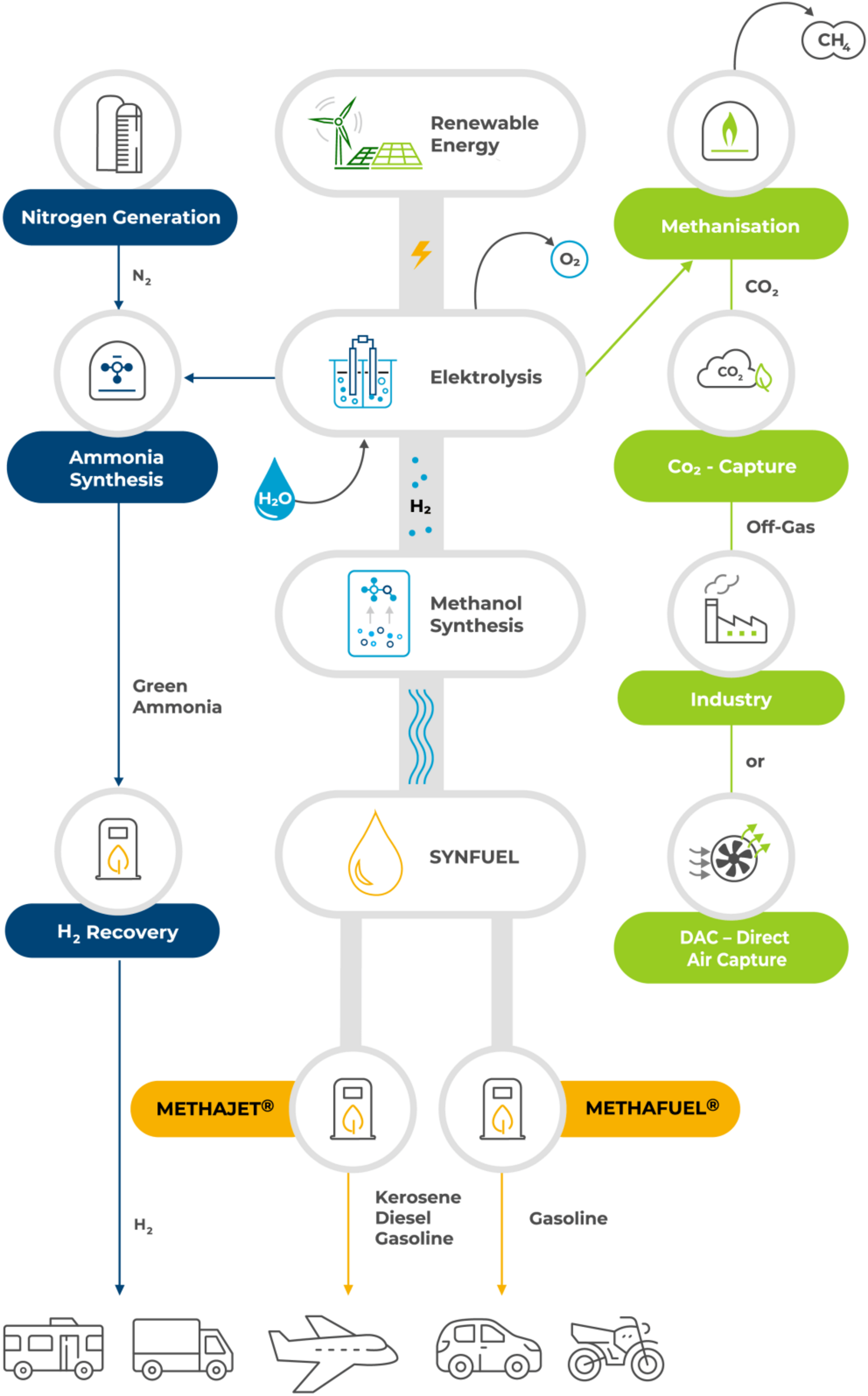

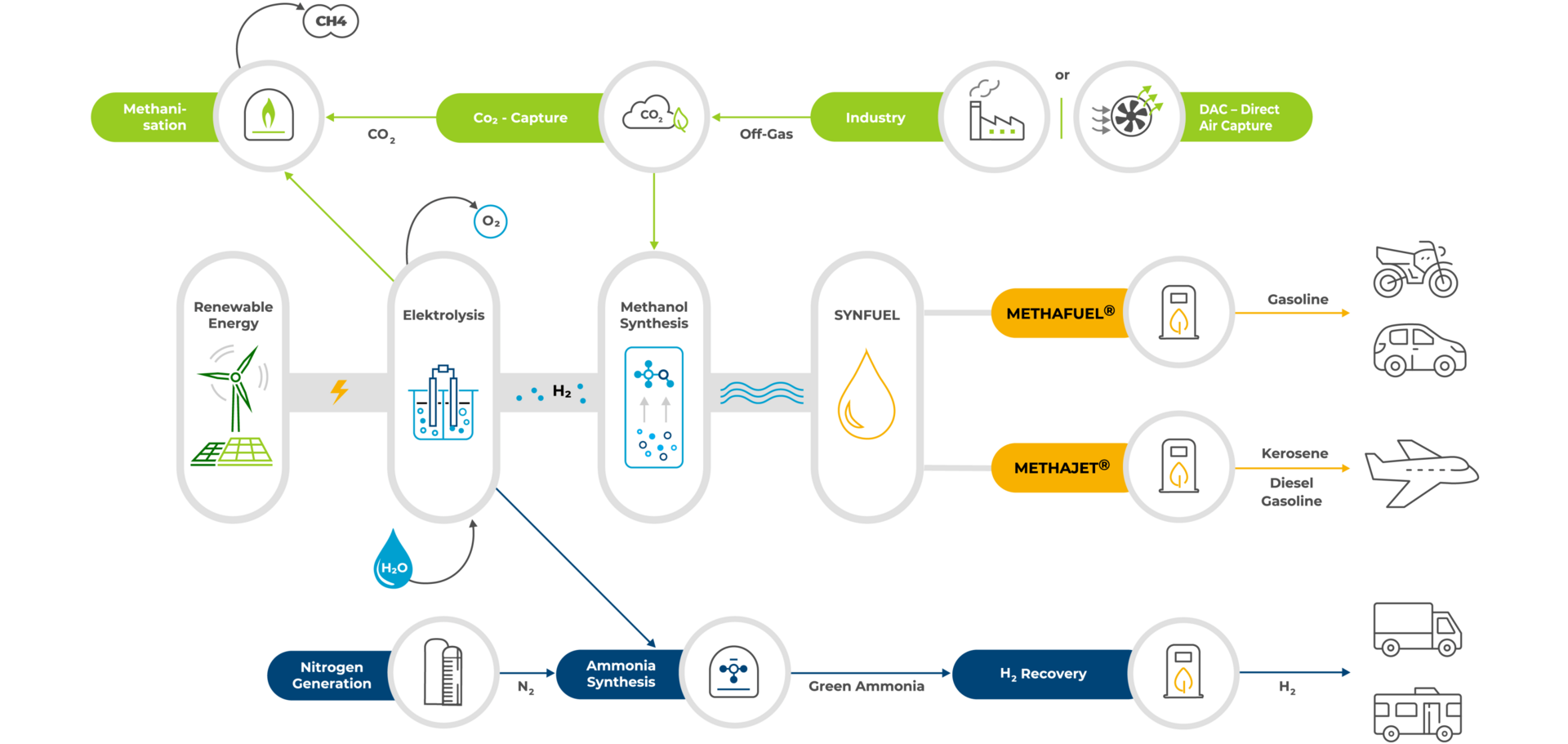

Renewable energies offer great potential for the manufacture of sustainable, climate-friendly chemical and fuel products. In addition to our own technologies for the production of synthetic fuels (e-fuels), we are able to implement various technologies by using power-to-X process chains (e. g. water electrolysis, methanol synthesis etc.). On the basis of our 60 years of expertise in the construction of large-scale industrial plants for the chemical industry, we have the necessary experience to integrate these new fields of application as well.

In doing so, we give support our Clients from the preparation of a feasibility study including technology selection to the turnkey construction of plants.

Water electrolysis

engineering the future of clean energy

Regenerative hydrogen is the key to energy transition. Incorporating regenerative electricity from solar, wind and hydropower sources, the separation of water into oxygen and hydrogen occurs in water electrolyzers. Our know-how is based on more than 300 MW installed electrolyzer capacity in the field of chlor-alkali electrolysis and the successful implementation of 13 plants built to date as well as a large number of other engineering projects all over the world.

Our expertise in the field of water electrolysis lies in the implementation of such electrolyzers, including the necessary units for water treatment as well as hydrogen drying and compression. Depending on the area of application of the plant at our Clients, we can recommend and implement a tailor-made technological solution - thanks to our broad overview of the market and the various suppliers of electrolyzers.

Hydrogen Derivatives

engineering advanced hydrogen solutions

Green hydrogen is used as feedstock for processing into various derivatives, such as methanol, methane or ammonia. We support our Clients in the selection of suitable technologies for each case of application (feedstock quality, plant capacity etc.) and in the implementation of the best technological solution for the respective individual business case. We have access to various technology providers/licensors and we are able to integrate the selected technology into an existing plant network (brown field) or implement it in a new plant (green field). The planning and realization of plants on the basis on third-party technologies has been an integral part of our service portfolio for 60 years now.

E-Fuels

engineering sustainable fuels for tomorrow

Since 2008 we have been working successfully on the development and application of our own technologies for climate-neutral fuels on the basis of methanol. The advantage lies in the cost-effective production of methanol in regions with favorable energy conditions, use of existing infrastructure for its transportation and the conversion into e-fuels at competitive costs. This will help immediately to reduce CO2 emissions from fossil fuels.

Our market-ready technology produces gasoline that is compliant with DIN EN 228. Therefore, it can be used 100 % in the existing motor fleet, and it can also be added to conventional gasoline in any quantity as drop-in product. This gasoline has been successfully tested in various applications, including the 24-hours race on the Nürburgring and the FIM WorldSBK.

Would you like to learn more about these unique, patented technologies?