Chlor-Alkali Solutions

In addition to the construction of new membrane plants on greenfield sites, our know-how also lies in the conversion of existing process plants. Our extensive experience means we are specialists in the entire process chain, from salt dissolution to electrolyzers and on to the further processing of electrolysis products.

Know-How

In combination with first-class electrolyzer technology, such as that of our technology partner Asahi Kasei Corporation, we offer you the following benefits:

- Low energy consumption

- No environmental impact from amalgam or asbestos

- High production purity

- Simple handling and operation

- Low investment and operating costs

Electrolysis occurs with modern membrane electrolyzers, in accordance with the conclusions of the BREF document (Best Available Technology Reference Document) for the chlor-alkali industry.

Raw materials and products

The electrolysis of a salt solution (NaCl or KCl solution) produces the products caustic soda or potash (NaOH or KOH solution), chlorine (Cl2) and hydrogen (H2).

The salt comes from seawater (solar salt NaCl), mineral deposits (rock salt NaCl or KCl) or salt from evaporation processes (evaporated salt: NaCl or KCl).

The primary products of chlor-alkali electrolysis (NaOH as 32 % caustic or KOH as 29 % to 32 % caustic, hydrogen gas and chlorine gas) can be transformed into the following storable commercial products:

- Hydrochloric acid 32 % to 36 %

- Caustic soda 50 % / potash 50 %

- Liquid chlorine:

- stored at low pressure, e.g.: -34 °C / 1 bar (abs.) or

- stored at high pressure, e.g.: +20 °C / 6.8 bar (abs.)

The chlorine can also be transported directly for further processing as a dry and compressed gas via a pipeline system.

Technology and electrolyzers

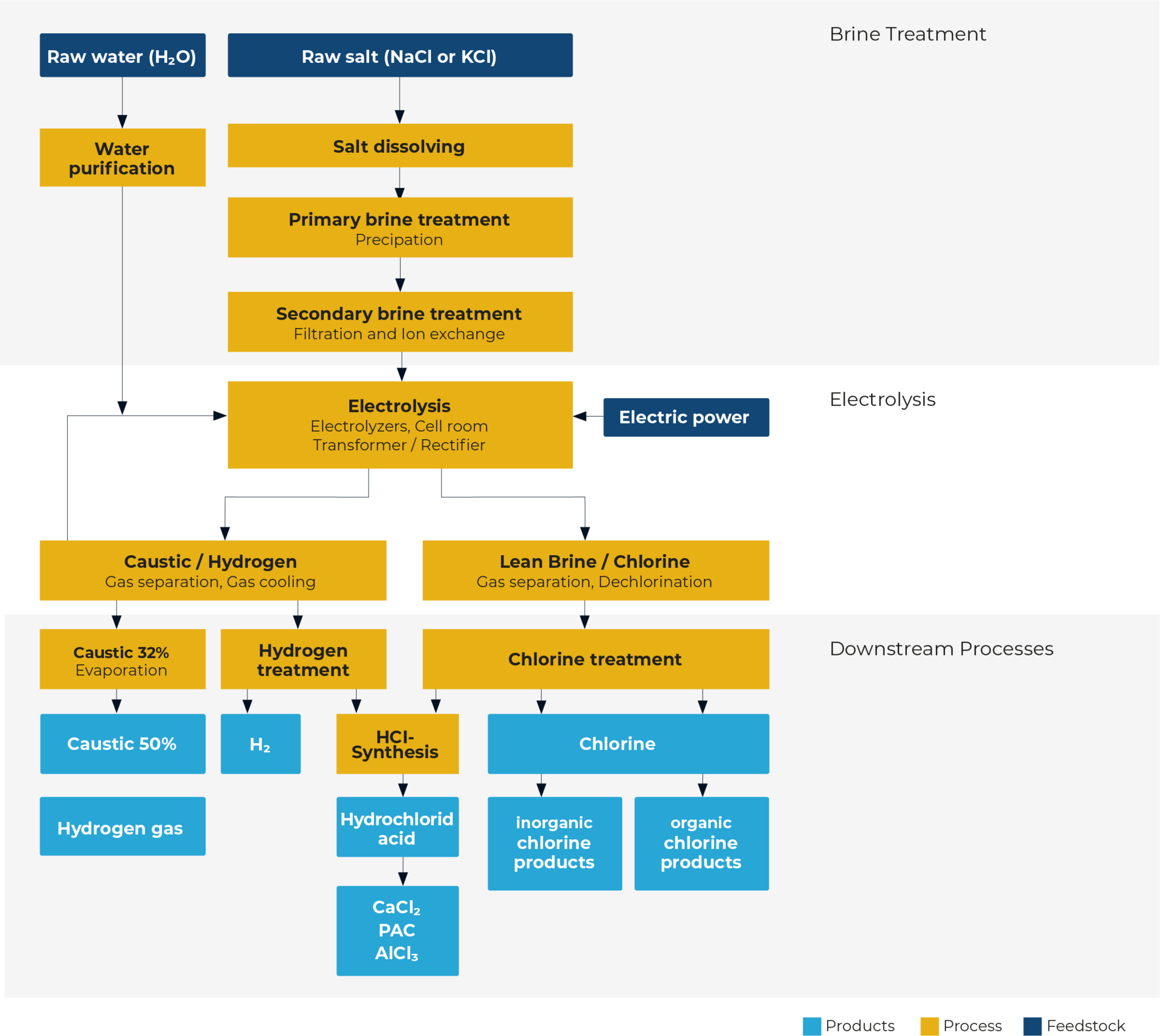

Our technological range of services comprises the entire chain from salt dissolution, brine preparation and electrolysis to the further processing of the products. (Graphic representation)

Technology

The complete chlor-alkali plants include the following sections:

- Salt dissolution from rock salt, evaporated salt or solar salt

- Primary brine purification

- Fine brine purification

- Electrolysis with transformer and rectifier

- Catholyte and hydrogen treatment

- Anolyte and chlorine gas treatment

- Drying, compression, liquefaction and storage of chlorine

- Evaporation and loading of caustic

- Optional: NaOH (KOH) flaking or prilling, bagging and loading

- Chlorine absorption system: Emergency absorption, optionally with hypochlorite production

- Hydrochloric acid synthesis (HCl 30 % - 36 %)

Our Chlor-Alkali reference plants

Chlor-alkali electrolysis

2020

client

Bondalti Cantabria S.A.

location

Torrelavega, ES

contract

EPC

capacity

65.000 t/a Chlorine, 72.000 t/a Caustic soda

completion

2020

- Project Management

- Basic Engineering

- Detail Engineering

- Procurement and deliveries

- Assembly

- Assembly supervision

- Commissioning and start-up

- Training of personnel

Chlor-alkali electrolysis

2019

client

PETKIM Petrokimya Holding A.S

location

Aliaga/Izmir, TR

contract

EP

capacity

112.000 t/a Caustic Soda, 100.000 t/a Chlorine

completion

2019

- Project management

- Basic Engineering

- Detail Engineering

- Procurement

- Installation supervision

- Deliveries

- Assembly supervision support

- Commissioning and commissioning support

- Operator training

Chlor-alkali electrolysis

2017

client

Neolyse Ibbenbüren GmbH, Produktions-Joint-Venture von Evonik Industries AG & Akzo Nobel Industrial Chemicals GmbH

location

Ibbenbüren, Uffeln, DE

capacity

130.000 t/a caustic potash, 82.000 t/a Chlorine

completion

2017

- Project Management

- Basic Engineering

- Detail Engineering

- Procurement support

- Installation supervision

- Commissioning

- Training

Chlor-alkali electrolysis

2016

location 8,250 t/y chlorine Design: 25,000 t/a potash 16,500 t/a chlorine

Soligorsk, BY

capacity

Capacity: 12,500 t/y potassium hydroxide

completion

2016

- Project Management

- Basic and Detail Engineering

- Tasks for construction, steel construction and technical building equipment

- Procurement and deliveries

- Installation supervision support

- Commissioning and commissioning support

- Operator training

Chlor-alkali electrolysis

2015

client

OOO Soda-Chlorat

location

Beresniki, RU

contract

EPCM

capacity

40.000 t/a KOH, 26.000 t/a Chlorine

completion

2015

- Projektmanagement

- TEO Projekt (Erweitertes Basic Engineering)

- Detail Engineering

- Aufgabenstellungen für Bau, Stahlbau, Heizung, Lüftung

- Lieferungen

- Unterstützung bei der Montageüberwachung

- Inbetriebnahmeunterstützung

- Personalschulungen

Chlor-alkali electrolysis

2015

client

Potasse et Produits Chimiques SAS

location

Thann, FR

contract

EPC

capacity

68.400 t/a caustic potash, 43.200 t/a Chlorine, 4.000 t/a Bromine

completion

2015

- Project Management

- Basic Engineering

- Detail Engineering

- Procurement and deliveries

- Assembly

- Assembly supervision

- Staff training

- Commissioning

Chlor-alkali electrolysis (extension)

2015

client

Donau-Chemie Aktiengesellschaft

location

Brückl, AT

contract

EP+Cm

capacity

90,4 Tons per day Chlorine

completion

2015

- Project Management

- Advanced Basic Engineering

- Detail Engineering

- Deliveries

- Support with assembly supervision

- Staff training

- Commissioning support

Sodium hypochlorite plant

2015

client

Wassertechnik Essen GmbH

location

Moskau, RU

contract

EPC

capacity

10.000 t/a Chlor, 50.000 t/a Sodium hypochlorite

completion

2015

- Project Management

- Basic Engineering

- Detail Engineering

- Deliveries

- Assembly

- Assembly supervision

- Staff training

- Commissioning

Chlor-alkali electrolysis (capacity expansion)

2012

client

OAO Sajanskchimplast

location

Sajansk, RU

contract

EPCM

capacity

180.000 t/a Chlorine

completion

2012

- Project Management

- Basic Engineering

- Detail Engineering

- Procurement services

- Deliveries

- Installation supervision

- Commissioning support

- Staff training

Chlor-alkali electrolysis

2006

client

OAO Sajanskchimplast

location

Sajansk, RU

contract

EPCM

capacity

169.000 t/a Caustic Soda; 150.000 t/a Chlorine

completion

2006

- Project Management

- Basic Engineering

- Detail Engineering

- Procurement services

- Deliveries

- Installation supervision

- Staff training

- Commissioning support

Chlor-alkali electrolysis

2001

client

PO Navoiazot

location

Navoi, UZ

contract

EPCM

capacity

26.000 t/a Caustic Soda Chlorine, 23.000 t/a Chlorine

completion

2001

- Project Management

- Basic Engineering

- Detail Engineering

- Procurement services

- Deliveries

- Installation supervision

- Staff training

- Commissioning support